Product Brief

Description

Laser reflective mirrors, also known as total laser reflect mirror, generally made from Molybdenum, Copper, and Silicon.

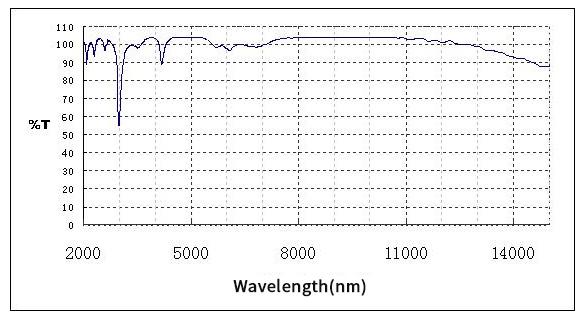

There is no coating on Mo mirror. It can work in rugged environment, withstand high laser power, is resistant to wiping and has long service life. But the reflection rate of Mo mirror is not high. Copper is mostly used for making high power mirrors for CO2 laser. Silicon is the most popular material for making laser reflective mirrors with coating, it has good optical thermal properties and high reflectivity.

The reflectivity of silicon co2 laser reflect mirror developed by SPT Laser is up to 99. 8%, which is the leading position in the laser industry.

Parameters

The co2 laser reflective mirror is an important component in the laser light transmission system. In the CO2 laser light path, the laser reflect mirror can be used in two ways. The mirror in the laser tube can be used as a tail mirror. The base of the mirror has a certain curvature, which can make the laser oscillate. In some laser designs, the laser reflective mirror can change the light in the laser tube and reduce the length of the laser tube. Outside the laser tube, the co2 laser reflect mirror and laser focus lens cooperate to form a complete optical path, it allows the laser machine to save space, reduces laser loss, and optimises the laser’s working power preservation.

|

Based material:silicon,molybdenum,quartz |

Diameter tolerance:+0.0/-0.1mm |

|

Thickness tolerance:±0.1mm |

Surface type:λ/[email protected] |

|

Surface quality:S1:40-20 |

Parallelism:<1 are min |

|

Effective aperture:>90% |

Bevelling side:0.2×45°45° |

|

Coating:MMR、EG、ES、PG |

|

| Model | Material | Diameter (mm) | Thickness (mm) | Reflectivity % |

| SPT0.50-0.08 | Silicon | 12.7 | 2 | >99.5 |

| SPT 0.61-0.08 | Silicon | 15.4 | 2 | >99.5 |

| SPT 0.71-0.09 | Silicon | 18.05 | 2.5 | >99.5 |

| SPT 0.75-0.12 | Silicon | 19.05 | 3 | >99.5 |

| SPT 0.78-0.12 | Silicon | 20 | 3 | >99.5 |

| SPT 0.98-0.12 | Silicon | 25 | 3 | >99.6 |

| SPT 1.0-0.12 | Silicon | 25.4 | 3 | >99.8 |

| SPT 1.10-0.12 | Silicon | 27.94 | 3 | >99.6 |

| SPT 1.20-0.12 | Silicon | 30 | 3 | >99.8 |

| SPT 1.50-0.16 | Silicon | 38.1 | 4 | >99.8 |

| SPT 2.0-0.19 | Silicon | 50.8 | 5 | >99.8 |

| SPT M-20-3.0 | Mo Mirror | 20 | 3 | >96 |

| SPT M-25-3.0 | Mo Mirror | 25 | 3 | >96 |

| SPT M30-3.0 | Mo Mirror | 30 | 3 | >96 |

Problems & Solutions

Because the laser mirror will absorb the heat of laser, cause the deformation of film and base, and affect the quality of laser beam, so the cooling measures for the lens are necessary. Water and air cooling are the two usual cooling methods. For example, in the field of high-power laser processing industry, usually cooling water tank on the back of copper mirrors to make the water cooling reach the whole mirror surface. For medium power laser, the cooling method is usually air cooling or add water cooling laser reflect mirror mount.

The incorrect installation of laser reflect mirrors will lead to the deflection of optical axis, which makes it difficult to adjust the laser reflection path to the optimal state, thus affecting the laser processing effect. For example, can’t cut material very well, dirty cutting seam and so on.

Attentions

Laser heating can absorb dirt and contaminate the surface of co2 laser optical lens. Dust, oil vapour, water vapour, splashing of materials during cutting or marking, fingerprints and so on can contaminate the laser optical lens. Keep away from potential sources of contamination and maintain regular cleaning processes of laser lens. Under normal conditions, every worker should check the optical system before changing shifts to predict possible contamination or damage.

1. Always wear rubber/latex finger cots or gloves when operating laser lens. Dirt and oil stains on the skin can seriously contaminate the laser lens and greatly degrade its performance.

2. Do not use any tools to operate laser optical lens, including tweezers.

3. Out of protecting the lens, the laser lens should be placed on the wiping paper or cotton.

4. Do not place laser optical lens on hard or rough surfaces. The surface of laser optical lens can easily be scratched.

5. Do not clean or touch the exposed gold or copper surface.

6. Keep in mind that all the laser lens components are fragile.

1. Take off the laser mirror with a finger cot.

2. Blow the debris scattered on the surface of the laser mirror with an air bag and place it on a clean and soft cotton cloth.

3. Use clean degreased cotton balls and soak them in acetone before wiping the mirror surface.

4. Wash the mirror with acetone, then hold the corner of the wiping paper and place the paper on the laser mirror. Drag the paper slowly to remove the residual acetone, then dry the surface of the laser mirror.

5. Heavily polluted metal based co2 laser reflect mirrors can be cleaned with a minimum polishing agents to ensure the removal of diet at first. Then use the above series methods for cleaning.

6. Finally, carefully inspect the surface of the laser optical lens under intense light. Repeat the steps if there are residual contaminants.

Guarantee

Despite choosing the best optical materials and technology, we can not completely guarantee that all laser optical lens products will not appear any defects. We provide a 30-day quality litigation period for quality problems caused by defects in optical materials and manufacturing.

Service method:

After confirming the laser optical lens need to be sent back SPT LASER, please return in original manufacturing package or same package to keep the completely product appearance.

The following condition are not covered by warranty:

1.The polluted laser lens surface which lead to the breakdown of material and coating film.

2.The damage of coating film which cased by improperly storage, laser lens should be kept avoid humidity.

3.The damage of coating film which cased by improperly cleaning methods.

4.The damage of laser lens caused by external force.

Tel: 0086-769-26380380

Business: [email protected]

Service: [email protected]

Address: #3201, Dongjiang Star Commercial Center, Dongguan , Guangdong,China