Product Brief

Description

The co2 variable beam expander is an optical system consisting of two or more elements, which can change the size and divergence characteristics of the beam.

The CO2 variable beam expander has many applications:

- Obtain a smaller focus.

- Improve alignment of laser beam

- Reduce the beam diameter in acousto-optic or electro-optic modulators.

Improve symmetry and uniformity of spot energy distribution by using the spatial filter and the variable beam expander

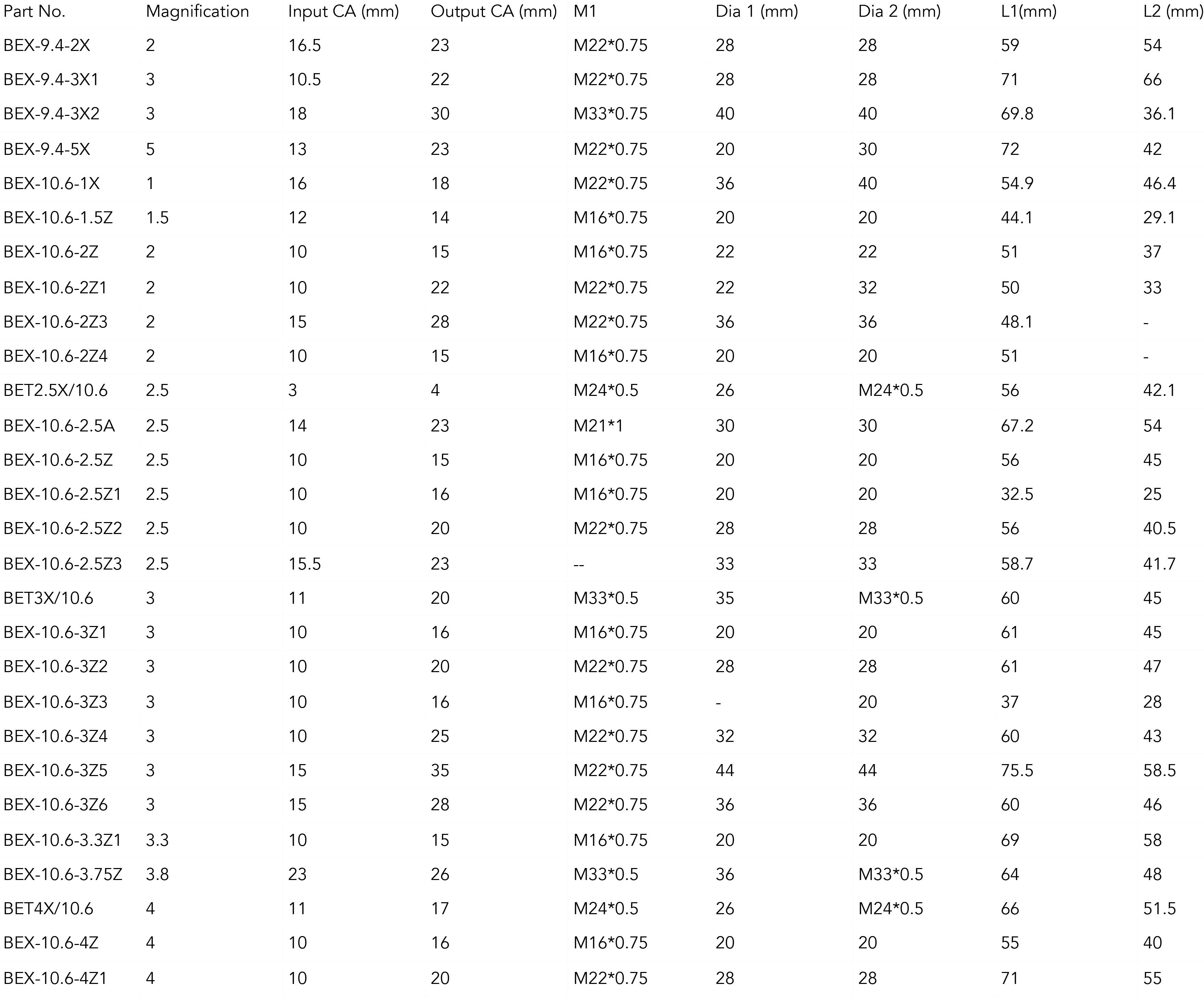

Parameters

Problems & Solutions

1. The variable beam expander is a non-focusing system, it can ensure the parallel collimation of the laser through the variable beam expander. It is widely used in precision cutting, marking, drilling and welding laser systems.

2. The variable beam expander according to the size of the spot of the optical-mechanical system and galvanometer system, combined with the laser source’s incident aperture. After the beam expanding, the beam diameter and the beam parallelism quality can be adjusted, so that the beam diameter can be enlarged, and a smaller and finer focus spot can be obtained.

3. The beam expander’s design and assembly require precise parameters for the lens’ optical axis, base and group concentricity. Larger focus spot will cause beam offset. Parallelism and inclination of the beam expander affect beam propagation, cutting, focal length, focus spot size and quality of the focusing system.

4. SPT’s engineers and technicians design and simulate operational status using a professional optical design software to precisely determine the installation of the beam expander and improve beam expander convenience of use and efficiency to support the customer's laser application system in its usage.

5. Our variable beam expander products are all designed with adjustable divergence angles, which can provide high-precision laser beam expander products with various systems of constant and variable magnification.

Attentions

Laser heating can absorb dirt and contaminate the surface of laser optical lens. Dust, oil vapour, water vapour, splashing of materials during cutting or marking, fingerprints and so on can contaminate the laser optical lens. Keep away from potential sources of contamination and maintain regular cleaning processes of laser lens. Under normal conditions, every worker should check the optical system before changing shifts to predict possible contamination or damage.

1. Always wear rubber/latex finger cots or gloves when operating laser lenses. Dirt and oil stains on the skin can seriously contaminate the laser lens and greatly degrade its performance.

2. Do not use any tools to operate optical lenses, including tweezers

3. For protection purposes, optical lenses should always be placed on the provided wipe paper or cotton cloth.

4. Do not place laser optical lenses on hard or rough surfaces. The surface of laser optical lens can easily be scratched.

5. Do not clean or touch the exposed surface of gold or copper.

6. Keep in mind that all the laser lenses components are fragile.

1. Take off the laser lens with a finger cot

2. Blow the debris scattered on the surface of the laser lens with an air bag and place it on a clean and soft cotton cloth.

3. Use clean degreased cotton balls and soak them in acetone before wiping the lens surface.

4. Wash the lens with acetone, then hold the corner of the wiping paper and place the paper on the lens. Drag the paper slowly to remove the residual acetone, then dry the surface of the lens.

5. Heavily polluted metal based mirrors can be first cleaned with polishing agent. The polishing agent should be at a minimum to ensure the removal of necessary dirt. Then use the aforementioned methods to clean.

6. Finally, carefully inspect the surface of the laser optical lens under intense light. Repeat the steps if there are residual contaminants.

Guarantee

Despite choosing the best optical materials and technology, we can not completely guarantee that all optical lens products will not appear any defects. We provide a 30-day quality litigation period for quality problems caused by defects in optical materials and manufacturing.

Tel: 0086-769-26380380

Business: [email protected]

Service: [email protected]

Address: #3201, Dongjiang Star Commercial Center, Dongguan , Guangdong,China