Product Brief

Description

SPT laser focus lens is made of CVD Znse which imported from USA, Low material absorptivity, can withstand high power density, firm surface layer, not easy to fall off. The double-sided coating ZnSe laser focus lens, its main function is to reduce or eliminate the reflective light on the optical surface, to increase the transmittance of these components and reduce or eliminate the stray light of the system.

Antireflective films with various requirements have been designed for wide ranges of use: Single-wavelength antireflective coatings, broadband antireflective coatings, ultra-wide-band antireflective coatings, dual-band antireflective coatings, dual-wavelength antireflective coatings and so on. 10.6um, the common use wavelength in CO2 laser industry, can reach 99.8% transmittance.

As a most economical transmission laser focus components, laser focus lens is widely used in laser heat treatment, welding, cutting and infrared radiation collection. In order to obtain satisfactory performance and achieve the purpose that the surface of the laser lens should be towards the direction of imputed light beam towards the conjugate distance the longer end. (object distance and image distance are called conjugate distance).

Parameters

| Material:ZnSe/GaAs | Wavelength:10.6μm |

| Surface quality:20-10 scratch and dig | Centration:<3' arc minutes |

| Focal length tolerance:±1% | Bevelling:<0.2x45° |

| Diameter tolerance:+0.0/-0.12mm | Effective aperture:>90% |

| Thickness tolerance:±0.2mm | Coating:R<0.5% per surface @10.6μm |

| Surface Accuracy:4<λ/2per 1” [email protected] |

|

Model |

Diameter (mm) |

Focal Length (mm) |

Thickness (mm) |

Material |

|

SPT12.7-2.0-1.8 |

12.0 |

50.8 |

1.8 |

PVDZnSe / GaAs |

|

SPT14.5-1.5-1.8 |

14.5 |

38.1 |

1.8 |

CVD ZnSe |

|

SPT14.5-2.0-1.8 |

14.5 |

50.8 |

1.8 |

CVD ZnSe |

|

SPT15.26-1.5-1.8 |

15.26 |

38.1 |

1.8 |

CVD ZnSe |

|

SPT16.0-1.5-2.0 |

16.0 |

38.1 |

2.0 |

CVD ZnSe |

|

SPT16.0-2.0-2.0 |

16.0 |

50.8 |

2.0 |

CVD ZnSe |

|

SPT18.0-1.5-2.0 |

18.0 |

38.1 |

2.0 |

CVD/PVD ZnSe |

|

SPT18.0-2.0-2.0 |

18.0 |

50.8 |

2.0 |

CVD/PVD ZnSe |

|

SPT18.0-2.5-2.0 |

18.0 |

63.5 |

2.0 |

CVD/PVD ZnSe |

|

SPT18.0-3.0-2.0 |

18.0 |

76.2 |

2.0 |

CVD/PVD ZnSe |

|

SPT18.0-4.0-2.0 |

18.0 |

101.6 |

2.0 |

CVD/PVD ZnSe |

|

SPT19.05-1.5-2.0 |

19.05 |

38.1 |

2.0 |

CVD/PVD ZnSe |

|

SPT19.05-2.0-2.0 |

19.05 |

50.8 |

2.0 |

CVD/PVD ZnSe |

|

SPT19.05-2.5-2.0 |

19.05 |

63.5 |

2.0 |

CVD/PVD ZnSe |

|

SPT19.05-3.0-2.0 |

19.05 |

76.2 |

2.0 |

CVD/PVD ZnSe |

|

SPT19.05-4.0-2.0 |

19.05 |

101.6 |

2.0 |

CVD/PVD ZnSe |

|

SPT20.0-1.5-2.0 |

20.0 |

38.1 |

2.2 |

CVD ZnSe/ GaAs |

|

SPT20.0-2.0-2.0 |

20.0 |

50.8 |

2.2 |

CVD ZnSe/ GaAs |

|

SPT20.0-2.5-2.0 |

20.0 |

63.5 |

2.2 |

CVD ZnSe/ GaAs |

|

SPT20.0-3.0-2.0 |

20.0 |

76.2 |

2.5 |

CVD ZnSe/ GaAs |

|

SPT20.0-4.0-2.0 |

20.0 |

101.6 |

2.5 |

CVD ZnSe/ GaAs |

|

SPT1.0"-2.0-3.0 |

25.4 |

50.8 |

3.0 |

CVD ZnSe |

|

SPT1.0"-2.5-3.0 |

25.4 |

63.5 |

3.0 |

CVD ZnSe |

|

SPT1.0"-3.0-3.0 |

25.4 |

76.2 |

3.0 |

CVD ZnSe |

|

SPT1.0"-4.0-3.0 |

25.4 |

101.6 |

3.0 |

CVD ZnSe |

|

SPT1.0"-5.0-3.0 |

25.4 |

127.0 |

3.0 |

CVD ZnSe |

|

SPT1.1"-2.0-3.0 |

27.94 |

50.8 |

3.0 |

CVD ZnSe |

|

SPT1.1"-2.5-3.0 |

27.94 |

63.5 |

3.0 |

CVD ZnSe |

|

SPT1.1"-3.0-3.0 |

27.94 |

76.2 |

3.0 |

CVD ZnSe |

|

SPT1.1"-4.0-3.0 |

27.94 |

101.6 |

3.0 |

CVD ZnSe |

|

SPT1.1"-5.0-3.0 |

27.94 |

127.0 |

3.0 |

CVD ZnSe |

|

SPT1.5"-3-4.0 |

38.1 |

76.2 |

4.0 |

CVD ZnSe |

|

SPT1.5"-5-4.0 |

38.1 |

127.0 |

4.0 |

CVD ZnSe |

|

SPT 1.5"-7.5-4.0 |

38.1 |

190.5 |

4.0 |

CVD ZnSe |

|

SPT 1.5"-5-0.31" |

38.1 |

127.0 |

7.87 |

CVD ZnSe |

|

SPT1.5"-7.5-0.31" |

38.1 |

190.5 |

7.87 |

CVD ZnSe |

|

SPT 1.5"-5.0-0.35" |

38.1 |

127.0 |

9.00 |

|

Problems & Solutions

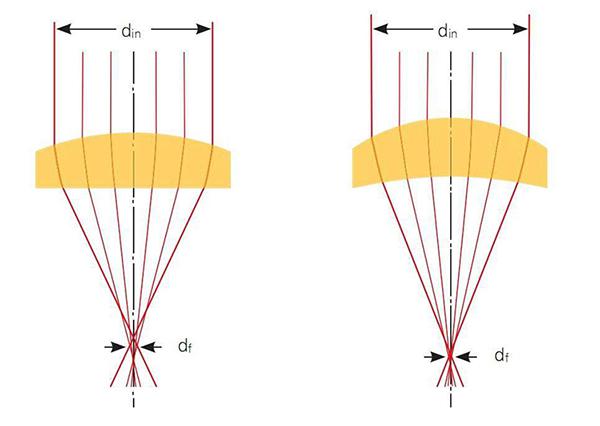

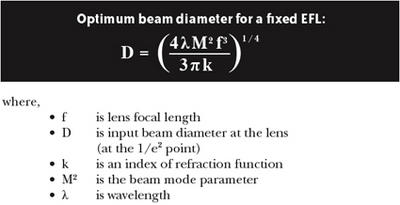

How to determine the beam diameter input with the laser optimal lens focal length?

Considering the mechanical design of the system, the focal length of the laser lens is often limited. For example, depending on the limitation, there is a minimum distance between the laser focus lens and the workpiece. In this case, the most practical method is to select a laser lens with focal length meeting the restriction of the mechanical part of the system, and then change the diameter of the input beam according to the laser lens to reduce the focus size to a minimum.

In order to determine the input beam diameter to minimise the spot size, we first derive the beam diameter, then set the derivative to 0 to get the minimum spot size according to the equation for calculating the spot size. Equations as following:

If the concave-convex laser lens is made of zinc selenide, its focal length limit is 5.00", that is 127 mm. We can calculate that the optimum input beam diameter is 26 mm. By substituting this value into the equation for calculating the size of the spot, the size of the spot becomes 86μm, which is the same as the number we see in the section "Determining the size of the spot".

If we calculate the Sulphur selenide flat convex laser lens with a focal length of 5.00", we can get an optimum input beam diameter of 24 mm, which provides a focal diameter of 96μm.

If the existing laser beam diameter in the system is far from the calculated input beam diameter, please enlarge or reduce the laser beam diameter to make it equal to this size. To enlarge or reduce the beam diameter, you can use a beam expander or concentrator, or you can use multiple laser lens to make your own beam expander or concentrator.

If it is not possible or desirable to change the beam diameter of the system, you need to figure out what focal length to use to minimise the spot size.

For that, calculate the derivative of the focal length based on the equation for calculating the size of the spot, and then set the derivative to 0 to get the minimum value of the spot. Equations. As following:

After finding the optimal focal length, you can find the corresponding laser lens with the closest focal length value in our catalogue.

As mentioned before, as focal length or diameter of the input beam are limited, there is a limit on the size of the focus that can be obtained. If the minimum spot calculated is larger than the size required in the current application, you must change some optical system parameters.

Note:

For high power CO2 lasers, the diameter of laser optical lens is generally not recommended to be larger than 1.5 times of the beam diameter (1/e2). If it is larger than this multiple, the possibility of thermal deformation will increase. The reason for this is that the distance between the heated area in the center of the laser lens and the cooler area in the edge increases, which leads to a too large thermal gradient of the whole optical element.

Attentions

Laser heating can absorb dirt and contaminate the surface of optical lens. Dust, oil vapour, water vapour, splashing of materials during cutting or marking, fingerprints and so on can contaminate the optical lens. Keep away from potential sources of contamination and maintain regular cleaning processes of laser lens. Under normal conditions, every worker should check the optical system before changing shifts to predict possible contamination or damage.

1. Always wear rubber/latex finger cots or gloves when operating laser lens. Dirt and oil stains on the skin can seriously contaminate the laser lens and greatly degrade its performance.

2. Do not use any tools to operate optical lens, including tweezers.

3. Out of protecting the lens, the lens should be placed on the wiping paper or cotton.

4. Do not place optical lens on hard or rough surfaces. The surface of optical lens can easily be scratched.

5. Do not clean or touch the exposed gold or copper surface.

6. Keep in mind that all the laser lens components are fragile.

1. Take off the laser lens with a finger cot.

2. Blow the debris scattered on the surface of the laser lens with an air bag and place it on a clean and soft cotton cloth.

3. Use clean degreased cotton balls and soak them in acetone before wiping the lens surface.

4. Wash the lens with acetone, then hold the corner of the wiping paper and place the paper on the lens. Drag the paper slowly to remove the residual acetone, then dry the surface of the lens.

5. Heavily polluted metal based lens can be cleaned with a minimum polishing agents to ensure the removal of diet at first. Then use the above series methods for cleaning.

6. Finally, carefully inspect the surface of the optical lens under intense light. Repeat the steps if there are residual contaminants.

Guarantee

Despite choosing the best optical materials and technology, we can not completely guarantee that all laser optical lens products will not appear any defects. We provide a 30-day quality litigation period for quality problems caused by defects in optical materials and manufacturing.

1.The polluted laser lens surface which lead to the breakdown of material and coating film.

2.The damage of coating film which cased by improperly storage, laser lens should be kept avoid humidity.

3.The damage of coating film which cased by improperly cleaning methods.

4.The damage of laser lens caused by external force.

Tel: 0086-769-26380380

Business: [email protected]

Service: [email protected]

Address: #3201, Dongjiang Star Commercial Center, Dongguan , Guangdong,China