Recently, the weather is getting hotter and the average temperature is about to exceed 34°C. With intermittent rain, the humidity in the air also has been greatly increased. This environment is undoubtedly fatal to laser equipment that requires water cooling during operation.

In hot and humid environment, it is easy to cause condensation inside the laser equipment during the operation, the performance of the laser tube or the RF laser may be affected,and even serious damage may be caused.

Laser condensation

Then what is condensation?

Condensation refers to the phenomenon that when the water vapor in the air reaches a saturated state, if the ambient temperature continues to drop, the supersaturated water vapor in the air condenses into water and precipitates. Simply put, when we put an object under a certain temperature, humidity and pressure, gradually reduce its temperature, when the temperature of the object drops below the "dew point temperature" of the environment (that is, the temperature at which the air around the object precipitates "condensed water"), water dew will precipitate on the surface of the object, it iscalled condensation. For example, when you walk outdoors from an air-conditioned room with glasses in summer, your glassesturn foggy, which is also akind of condensation.

Common condensation phenomenon - fogging of glasses

What harmcan be causedto the laser fromcondensation?

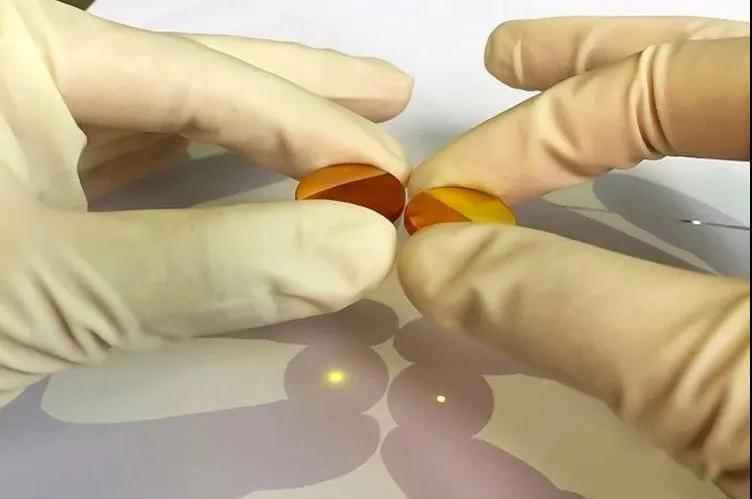

For laser cavities, optical components, and some electronic modules of lasers that require water cooling during operation, if the laser runs in a high-temperature and high-humidity environment for a long time,it is easy to see condensation on the surface of the object. This increases the failure probability of the electronic module when it is soaked in water, and may also cause theoutput lens to be contaminated by water mist and become unusable or burnt.

Laser lens

Pay attention to details and prevent condensation

Since condensation will cause serious damage to the laser, we must deal with the details, do a good job on protection, and take precautions.

Working environment with constant temperature and humidity

When the laser equipment is not working, the chiller should be kept being turned off to reduce the chance of condensation caused by excessive cooling for a long time.

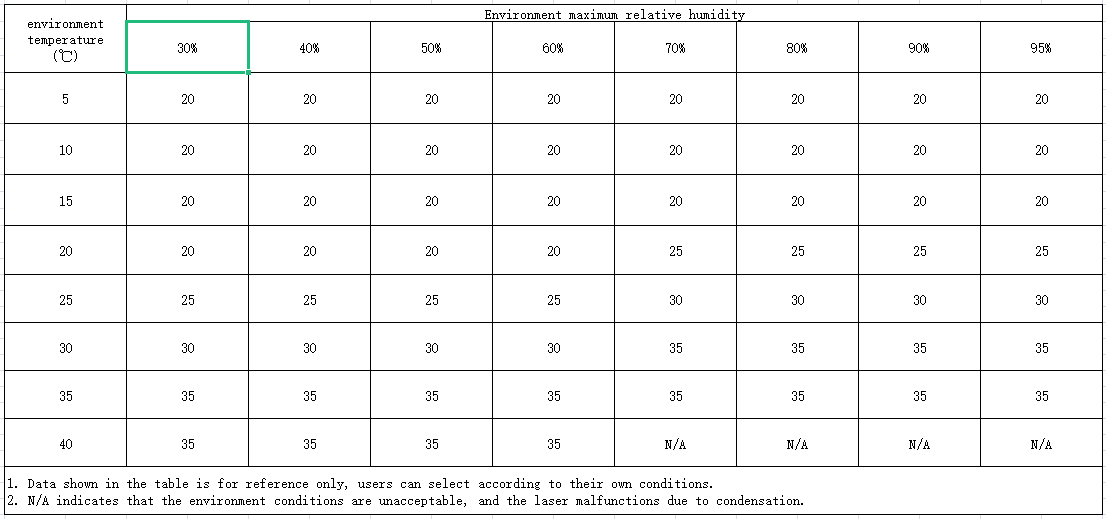

When the radio frequency laser is working, the ambient temperature is required to be controlled at 5°C to 40°C, and the maximum temperature of the laser surface should be below 60°C. It is recommended that you control and match the room temperature and the maximum relative humidity of the environment according to the actual use conditions to create a working environment with constant temperature and humidity for the laser equipment.

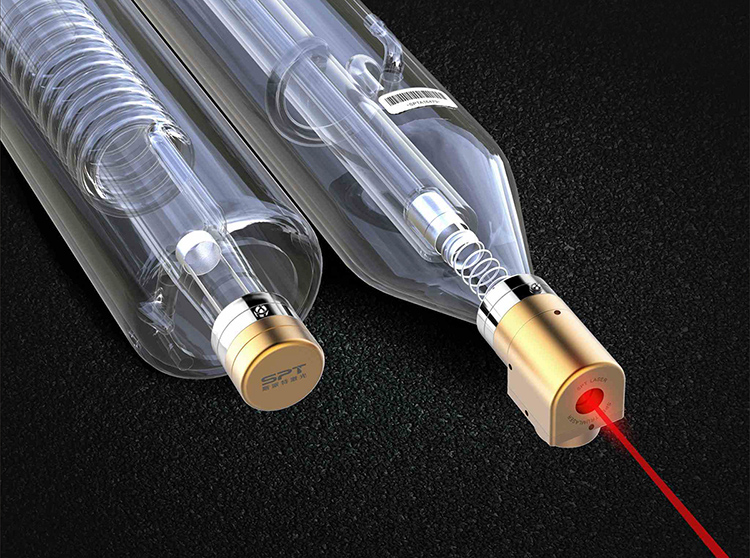

CO₂ RF Laser

You can also set the cooling water outlet temperature according to the on-site environment and ensure that it is higher than the corresponding dew point temperature. The outlet temperature of the refrigeration unit also needs to meet the water temperature of the laser and other cooling requirements.

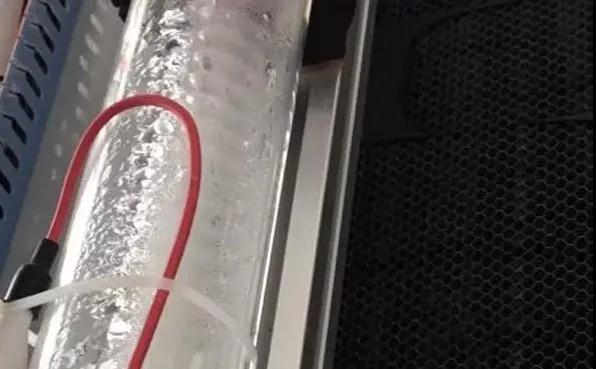

The temperature of the cooling water should not be too different from the room temperature. If the cooling water temperature is too low, small water droplets will easily condense on the surface of the laser, that is, condensation, which will easily cause high-pressure ignition and interfere with the normal operation of the equipment. Take the use of laser tube as an example. When high-voltage sparking is severe, it will cause high-voltage breakdown of glass water cooling, electrode terminal, etc., causing damage or even scrapping of the laser tube. At the same time, it will also greatly increase the risk of damage to other accessories on the laser equipment, such as laser power supplies, machine motherboard controllers and other electronic control components.

The cooling water temperature is too low, causing condensed water on the entire laser tube

At the same time, we should pay attention that it is summer now. In addition to preventing equipment condensation, we must also note that the temperature of the cooling water should not be too high. Excessively high cooling water temperature will prevent the laser from being properly cooled and dissipated during operation, resulting in poor laser mode, reduced laser tube cutting ability, and even increased risk of laser equipment damage. For example, when the CO₂ laser tube is working, if it is not cooled for a long time, it will damage the lens in the laser tube cavity. The glue between the water cooling jacket and the lens may be denatured and eventually fail to work or be damaged.

When the laser tube is working, the water temperature of the cooling water should be kept at 18~25℃, and the maximum should not exceed 30℃; if the radio frequency laser is operated in an air-conditioned working environment, the chiller temperature can generally be set to 25℃.

However, the specific cooling water temperature also needs to be adjusted according to the ambient temperature and humidity. Take the radio frequency laser as an example. When the ambient temperature is 26°C and the maximum relative humidity of the environment is 80%, the temperature of the chiller should be set to 30°C.

For specific content, please refer to the table below:

The reference value set according to the ambient temperature and humidity of the chiller's cooling temperature

At present, the scope of application of industrial chillers is more and more extensive, and you can also use chillers with intelligent temperature control systems to prevent such problems.

Under normal circumstances, set the cooling water temperature in the chiller to within 5°C below the ambient temperature, and the machine can work normally. If your chiller does not have an intelligent temperature control system, you can also set the lower limit temperature of the chiller to 5°C lower than the maximum value of the ambient temperature.

Precautions

Regular maintenance of the laser lens and optical path lens should be in order, and please turn off the equipment and disconnect the power supply during maintenance, and seal the transmission optical path of the laser processing equipment.

Note: If the laser equipment is working in a dusty environment, please use filtered clean air or high-purity nitrogen to blow the external light path.

CO₂ Laser Tube

Countermeasures against condensation

If condensation has occurred on your laser equipment, we recommend that you take the following measures:

<> Turn off the laser equipment and chiller immediately and disconnect the power supply;

<> Wipe clean the condensed water attached to the outside of the laser device;

<> Clean the laser lens and optical path lens according to the correct method to ensure that the equipment is fully dry;

<> Adjust the cooling water temperature or ambient temperature to an appropriate range according to the actual situation;

<> The circuit board of the laser device may also have condensed water. Please wait until it is sufficiently dry before restarting.

If you still can't solve the problem after trying the above methods, please contact SPT Laser after-sale service immediately.

Finally, SPT reminds you that for your safety and unnecessary losses, please use your laser equipment correctly.