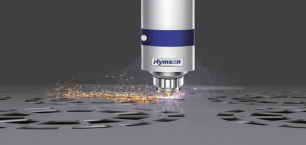

With the rapid development of the sheet metal intelligent equipment industry, the application of fiber laser cutting machines in the industry has become more and more widely accepted and adopted. Laser cutting instead of traditional cutting technology, on the one hand, greatly improves the efficiency of sheet metal processing; on the other hand, it also improves the intelligent and automated process of sheet metal processing. Traditional cutting requires a lot of human and material resources, while the automation and intelligence of laser cutting machines can greatly improve the efficiency of cutting. In the sense of development, it represents the rapid and vigorous development of the sheet metal industry.

After the fiber laser cutting machine became the mainstream processing equipment in this field, the market demand showed explosive growth, and the market retention rate continued to increase. However, the cutting efficiency of ordinary laser cutting machines is relatively low. According to the feedback of most users of fiber laser cutting machines, in the laser cutting process, with the increase of orders and the expansion of business scale, higher processing efficiency and quality have always been their pursuit. Therefore, this problem has always plagued customers, and it has always inspired fiber laser equipment manufacturers to increase research and development efforts to solve the pain and difficulties of this customer.

The emergence of the leapfrog process

The slow speed and efficiency of laser cutting machines affect the processing and production efficiency of an enterprise. To ensure the improvement of the cutting efficiency of the fiber laser cutting machine, the most important thing is to increase the cutting speed. In order to ensure that the cutting speed is increased, it is necessary to continuously invent new cutting processes. How to achieve faster and higher quality cutting is a common question among industry professionals. After assiduous research, Hymson's new ultra-fast leapfrog made a stunning appearance. With ultra-speed and high-efficiency technology, the efficiency of the laser cutting machine has been greatly improved.

What is leapfrog

According to the official definition, the leapfrog is the idle way of the laser cutting machine. Idle travel: the laser cutting machine moves without cutting.

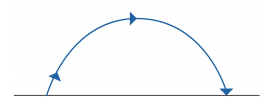

As shown in the figure, after the machine cuts hole 1, it needs to cut hole 2. The cutting head must move from point A to point B. Of course, it must be closed during the move. During the movement process from point A to point B, the machine runs empty, which is called idling.

However, if a parabolic motion is used between points AB instead of cutting at point A and then closing the cutting head to do cutting at point B, this can reduce the time for the cutting head to lift up, greatly reduce the users' cutting cost, and improve the user's cutting efficiency. This new process is called leapfrog.

The most notable feature of leapfrog is higher accuracy and speed. The laser cutting machine with leapfrog function is actually a technology that changes the Z-axis empty path.

Traditional leapfrog

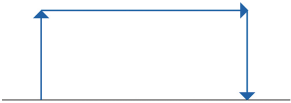

Many people know about the leapfrogging function of laser cutting equipment, but they don't understand its true nature. Leapfrogging can be divided into true and false leapfrogs. The traditional cutting system of the early laser cutting machine usually uses a rectangular movement, that is, the cutting head has to complete three actions: ascending (to a sufficiently safe height), translating and descending. This kind of cutting is time-consuming and inefficient.

Assume that the actions to be completed three times above are changed to be completed at the same time. When the cutting head moves from the starting point to the end point, it rises at the same time; when it approaches the end point, it descends at the same time. Compressing the moving time and movement of the cutting head can greatly improve the efficiency of the machine. As shown below:

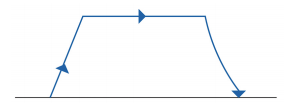

However, the leapfrog function of many laser cutting equipment on the market is not based on CNC planning, resulting in the existence of fake leapfrog. Fake leapfrog mainly manifests the jumping action diagonally upward, lifted into position and translated, and oblique arc falling. The continuity and rapidity of the action are not well highlighted in the action and time, resulting in stiff action and it’s easy to cause nozzle wear and low efficiency.

Brand new laser leapfrog

In the leapfrog movement of the laser cutting equipment, only the translation time from point A to point B is occupied, and the time of rising and falling is omitted. The frog jumped and caught the food; the frog jump of the fiber laser cutting machine caught high efficiency. The efficiency of laser cutting has been doubled.

The new leapfrog function based on CNC enables the cutting head to move between the cutting contours. Parabolic motion is used to prevent the cutting head from colliding with the workpiece. The take-off and landing are based on CNC real-time control. The position is accurate and rapid. Compared to the original overall empty space, shifting efficiency can be increased by more than 20%, greatly improving the efficiency of machine tool processing in terms of movement, efficiency and stability. Breaking the false leapfrog, the new high-speed leapfrog technology doubles the cutting efficiency.