RF CO2 laser application in non-metal film forming

The basic way of CO2 laser processing film is to expand the laser beam, then focus on the film products, the materials in the focus are gasified instantly, to achieve the cutting of materials, and finally get various shapes of film products.

With the development of film technology, various kinds of non-metallic films have been widely used in military industrial products and 3C electronic products. The non-metallic film products can be used for shielding seal, waterproof seal, heat conduction, insulation, appearance decoration, appearance protection, etc. The thickness of these films is generally between 0.1mm ~ 2mm, and the application scenarios are different in shape and shape. Due to the limitations of traditional manufacturing methods, such as cutting tools or mold forming, laser cutting has been widely used in non-metallic film forming.

The wavelength of CO2 laser is 10.6um, and the absorption rate of non-metallic film is higher with CO2 than other wavelengths. Therefore, CO2 laser is preferred for film processing and forming. The basic way of CO2 laser processing film is to expand the laser beam, then focus on the film products, the materials in the focus are gasified instantly, to achieve the cutting of materials, and finally get various shapes of film products. There are two kinds of common CO2 laser processing equipment: galvanometer scanning processing equipment and flying optical path scanning processing equipment. The RF excited diffusion cooled slab waveguide CO2 laser has become the preferred laser in thin film cutting and forming due to its advantages of good beam quality, high peak power, few maintenance and small volume.

SPT Q series RF CO2 LASERS

CO2 RF laser

The advantages of manufacturing film products with co2 RF laser cutting equipments are as follow:

Computer graphics, no mold required --- saving cost, quick response to market demand. Workable for both small batch proofing and mass production;

What you see is what you get—less requirements for operators’ skills, saves labor costs;

Maintenance-free and no consumables --- saves process time, labor cost, and running cost.

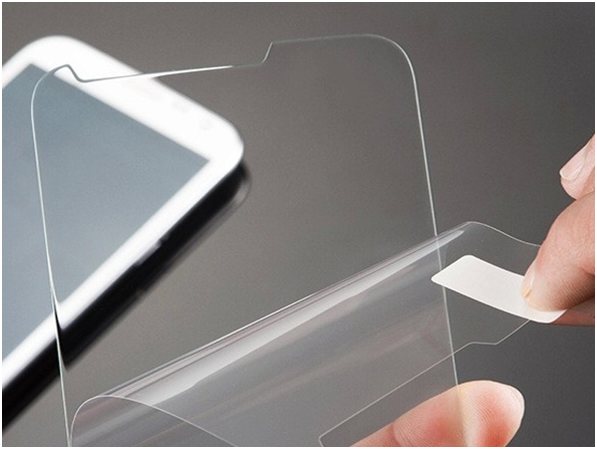

PET film on mobile

For processing thin film products, it requires neat cutting edges with small slope and no sawtooth, and small heat affect area. And there should be no residue accumulation on the edges. There are many factors that can affect the processing effect of CO2 RF laser machines. The following is a qualitative analysis of the factors for the film processing:

1. Wavelength---- there are four wavelengths of RF CO2 lasers, 10.6μm, 9.3μm, 10.2μm, and 9.6μm. Most non-metal materials are organic plastic products and polymer products. The light absorption rate of organic substances is low and it is very sensitive to the change of light wavelength, and with small differences in wavelength, the difference in absorbance can be very big. The difference in laser absorptivity of materials has a fundamental impact on the processing effect, so the wavelength of laser matters most on processing effect and these four wavelengths are reliably obtained from CO2 RF lasers. The co2 RF laser has a maintenance-free life of more than 20,000 hours, and can be used again after refilling when the power is weak. Reasonably maintained CO2 RF lasers can last more than 100,000 hours.

2. Laser power --- Co2 RF laser can output laser power from sevral watt to thousands of watt. Please choose laser with proper power according to the thickness and power absorptivity of film materials as well as demanded cutting speed. Generally, it’s easier to have best processing performance when the working power of laser on machine is no more than 80% of Max. output power of the RF laser.

3. Focus lens --- it’s very necessary to choose focus lens with proper focal length which decides the final laser spot size for processing. The focal length of cutting equipment with fly marking is normally 1~2.5inch. With same focal length, lens shape is optional in meniscus and plano convex. And meniscus lens can achieve better laser spot than plano convex one. As for co2 laser machine with galvo system, focal length of F-theta lens is normally 80~160mm. For very high demanding process, telecentric field lens will be required.

4. The cutting speed of thin film---The cutting speed determines the laser processing time and the amount of laser energy absorbed by the film and then affect the size of the cutting heat affected zone.The cutting speed is usually greater than 100mm /s for the film cutting and the terms of flying light path. The generally speed is greater than 500mm / s of Galvanometer scanning laser processing.It needs to pay attention to the combination of laser modulation frequency and speed to obtain smooth edges if the cutting speed reaches several kilometers per second.

5. Focus position--Although the film is very thin, it also has a certain thickness.The focus position is on the upper surface of the material, in the middle of the material, and on the lower surface of the material,even the top defocus and the bottom defocus.The selection of different focal points can affect the processing efficiency and processing effect.

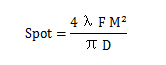

6. Laser mode---Laser mode describes the distribution of laser energy in a cross section of the laser beam perpendicular to the transmission direction.Laser mode is divided into horizontal mode and vertical mode. Most RF CO2 lasers are horizontal mode.The RF CO2 laser mode is simply divided into a basic mode and a multimode in the application.In order to obtain a fine processing effect, basic mode is in most cases chosen.The beam quality factor M2 of the laser output from the base mode is relatively small, generally less than 1.5.Calculation formula based on focused light spot:

Spot is the diameter of focusing spot,λ is the laser wavelength, F is the focal length of the focusing lens, and D is the size of the spot incident on the focusing lens.It can be seen from the calculation formula that the size of the focused spot is proportional to the beam quality factor M2.So choosing the fundamental mode and choosing a laser with a small beam quality factor can get a small focused spot and get better processing results.

7. Auxiliary gas---The auxiliary gas can blow away the smoke from the incision;Prevents contamination by waste and smoke;Diversion for laser thermal energy,Make the laser energy more concentrated on the material and enhance the laser cutting ability.According to cutting requirements, you can choose different combustion-supporting or flame-retardant gases.

8.Film material---The process is very complicated when laser cutting materials.Generally speaking,it including the conversion of light energy to heat energy conversion and distribution of heat energy on the workpiece and heat exchange between the workpiece and the surrounding environment when laser cutting plastic and other polymer materials.In short,one of the fundamental optical properties of film materials is absorption and conversion.The laser energy absorbed by the film material per unit time determines the overall absorbed energy,the laser light energy is irradiated on the surface of the material, and then converted into thermal energy, the surface temperature is high.The sum of the energy of the heating material, the vaporized material, and the mobile vaporization zone constitutes the energy distribution on the material.

PET film

As for the common PET material of the film material, It's an IMD film material with excellent performance and a thermoplastic polymer material, which has a complex molecular chain structure and an aggregated structure. PET is a composite material with excellent physical and chemical properties, because it has excellent mechanical and heat transfer properties, thermal stability, and optical transparency. The following table shows the thermal properties of PET film materials. From the table, it can be found that the melting temperature of PET materials is always 261 ° C, whether they are single-layer film materials, after amination, or multilayer PET film materials.

|

Sample |

Onset(℃) |

Tm (℃) |

△Tm (℃) |

△Hm (J/g) |

|

Original PET |

251.88±2.34 |

261.31±0.60 |

16.29 |

17.25±0.01 |

|

A/C PET |

250.88±0.01 |

262.20±1.52 |

17.86 |

22.50±0.05 |

|

Nanolayered film |

250.67±0.09 |

262.82±1.18 |

18.29 |

31.33±0.11 |

Thermal properties of PET film materials

From the thermal performance analysis of the PET film, the difference between different samples is small, and the cutting effect and efficiency is determined by the absorption efficiency of the PET film to the laser. The absorption coefficient of the PET film to the 10.6um wavelength is 0.5, So you can choose 10.6um laser to cut PET film. Some recent PET film cutting experiments by 9.3um laser, 10.2um laser, 9.6um laser, have obtained better results than 10.6um laser, which also shows the importance of laser wavelength selection for film cutting.

The above analysis shows It’s laser that the core device of the RF CO2 laser cutting a thin film. The correct selection of the laser wavelength and the absorption rate of the material is the basis for achieving the best cutting effect, at the same time, plus reasonable selection of the whole device and the appropriate process parameters, then the best effect and efficiency can be obtained. Of course, there are other software parameters that affect thin-film laser cutting, such as Q frequency, release time, processing leads, and so on.