Product Brief

Description

Parameters

Problems & Solutions

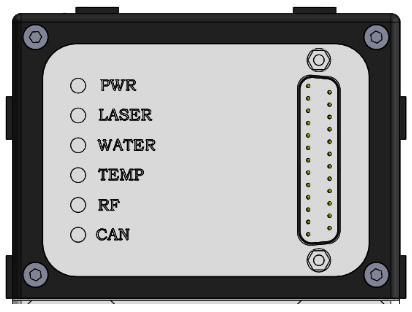

Indicator light

1. PWR: Green, power indicator light, flashes for 20 seconds when the power is turned on, indicating the rf co2 laser tube is initialized. Then there is a constant brightness, indicating that the rf co2 laser is in a working state.

2. LASER: Red, indicating the light output of the rf co2 laser : PWM signal is being input, laser light beaming.

3. WATER,TEMP,RF,CAN Light off.

1. WATER Red light on: Water cooling failure. Please check whether the water flow is normal.

2. TEMP Red light on: Temperature alarm, abnormal temperature of laser.

3. RF Red light on: Abnormal RF power supply.

4. CAN Yellow light on: CAN bus mode on

Please consult this manual and proceed according to the instructions.

If the problem remains, please do not attempt to self-repair, and contact our company or SPT laser authorized dealers for help.

Before storage the rf co2 lasers, drain out the water in the waterway. Once the waterway is drained, compressed air must be used to totally dry the waterway and prevent any small amount of water to remain in the laser waterways. In cold weather, a small amount of water can freeze, and may cause up to irremediable damage to the rf co2 lasers.

If you need to carry the rf co2 laser, please use the original laser packaging box. If the box is lost, please contact SPT Laser to purchase a new one.

Attentions

Regular routine inspections can help anticipate abnormalities and prevent laser damage:

1. Inspection of cooling water. Check the cooling water to ensure that it is clean, free of impurities and pollution. If there is any problem with the water quality, replace the cooling water immediately.

2. Check whether the water temperature of the rf co2 laser matches the ambient temperature. Look for any sign of condensation in the rf co2 laser shell, and if so, raise the water temperature appropriately.

3. If the environment is dusty, protect the rf co2 laser by blowing clean air or nitrogen。

4. Check if the laser protect window and each lens of the rf co2 laser equipment are clean. If there is dust, use high purity nitrogen to blow.

5. Inspect the label on the rf co2 laser and ensure that its operation complies with laser protection safety.

If there is dust or pollution on the laser lens or transmission optical lens, please clean it. Be sure to disconnect the DC power supply before cleaning. To ensure the cleanliness of laser lens and optical path lens, the transmission optical path of laser processing equipment should be sealed and protected. If the smoke in the working environment is too dense, clean air or blow high purity nitrogen. While storing and transporting rf co2 lasers, the operation should be standardised, and the lenses should not be damaged or contaminated.

Before cleaning, make sure that the DC power supply is disconnected.

When cleaning lenses, please wear special gloves.

When taking the laser lens, only the edge of the lens can be touched, the coating surface of the lens must not be touched.

The lens should be placed on soft non-woven cloth or a special cleaning cloth. It should not be placed directly on very hard or rough tables.

First use high purity nitrogen to clean the dust on the lens surface, and then choose whether to carefully wipe the lens according to the situation.

When wiping, the wiping cloth dipped in alcohol or acetone can only move in one direction on the lens surface. It can not be dragged back and forth. The wiping cloth can not be reused.

Check under clear light, and change to a mirror cloth or cotton ball if necessary and wipe again.

When cleaning laser lenses, the required materials are:

Material

Requirements

Gloves

No dust

Nitrogen

>99.9%

Alcohol

Spectroscopicaly pure grade

Acetone

Spectroscopicaly pure grade

Operating area

10,000-level optical super clean station

Cotton balls or swabs

Advanced surgical rank

Guarantee

The quality guarantee period of industrial co2 RF lasers produced by our company is as follows (including inventory period) from the manufacture date.

Q Series: 26 months

Service method:

If the co2 RF laser you purchased breaks down during the warranty period, please show relevant certificates, keep the factory logo and sealed label intact, product appearance must stay intact, and contact our company for a warranty replacement.

The following circumstances are not covered by the warranty:

1. Damaged warranty label on the rf co2 laser;

2. Laser faults and damages caused by human factors;

3. Failure or damage caused by incorrect wiring, installation and use which are not in accordance with the given instructions;

4. Failure or damage caused by natural disasters and other force majeure factors (such as earthquake and fire);

5. Other faults or damages not caused by quality problems of the rf co2 laser itself.

Tel: 0086-769-26380380

Business: [email protected]

Service: [email protected]

Address: #3201, Dongjiang Star Commercial Center, Dongguan , Guangdong,China